Tire tread scanners give better precision and consistency than manual gauges when people check tire tread. Measuring tire tread correctly keeps vehicles safe and helps tires work well. New tire tread scanner technology uses smart sensors and AI to find small wear patterns and changes in tread depth. These upgrades help drivers, technicians, and fleet managers find tread problems early and make smart decisions.

New sensor improvements let scanners find tread wear and contact stress at less than 0.5 mm. This makes measurements more accurate and helps keep vehicles safer.

Aspect | Detalii |

|---|---|

Sensor Improvements | High-precision pressure-sensitive films and sensors with less than 0.5 mm resolution |

Accuracy Impact | Better measurement accuracy of tire–road contact features |

Application | Lets people study pressure distribution for improved tire and pavement design |

Puncte cheie

Tire tread scanners check the whole tire fast and well. They find small wear that manual gauges can miss.

Digital scanners always give the same results. They remove human mistakes and save data for easy tracking.

Manual gauges only check one spot. They depend on how good the user is. This can cause mistakes and miss uneven wear.

Digital scanners help shops and fleets work faster. They keep better records and make vehicles safer.

Checking tire tread often with good tools lowers accident risks. It helps drivers know when to change tires.

Comparison

Precizie

Tire tread detectors are important for checking tires. Precision is important because small mistakes can make driving unsafe. Scanerele pentru profilul benzii de rulare a anvelopelor use special sensors to measure tread depth everywhere on the tire. These scanners collect data from thousands of spots on each tire. This helps them find small changes in tread depth and spot uneven wear. Manual gauges only check a few places on the tire. This means they can miss important details. If the technician picks the wrong spots, they might not see problems. Manual methods also depend on how careful the person is. This can lead to mistakes. Tire tread detectors with digital sensors help stop human error. They make measurements more accurate. In short, tire tread scanners are more precise than manual gauges.

Consistency

Consistency means getting the same results every time you check. Tire tread detectors with scanners give steady results because they always follow the same steps. The scanner does not need the technician’s judgment or hand position. It uses a sensor to scan the whole tire, so no part is missed. This lowers the chance of random mistakes. Manual gauges can give different results each time. The user might press harder or softer or pick different spots. Tire tread detectors with scanners also make digital records. These records help track tread depth changes over time. This makes it easier to compare results and see patterns. Consistent checks help drivers and managers make better choices about tires.

Note: Tire tread scanners make visual and digital reports. This helps people share results and builds trust with customers.

Reliability

Reliability means tire tread detectors give correct results again and again. Studies show tire tread scanners with 3D structured light have groove depth errors below 1% in good conditions. In harder cases, errors go up to 2.6%. These scanners work well even if the tire has problems or is not round. Tests show scanner results do not change much, even from different angles. Manual gauges have more problems. If the gauge is not lined up right, or if the rubber gets squished, results can change. Picking random spots can also hurt accuracy. Manual methods may average out measurements, which can hide uneven wear. Tire tread detectors with optical sensors do not touch the tire. They do not squish the rubber or depend on the user’s hand. In fleets, tire tread scanners and digital systems give real-time data and cloud analytics. This helps fleets know when to replace tires, cut downtime, and save money. Manual gauges cannot match this reliability or detection power.

Tire tread scanners check more of the tire and give better data than manual gauges.

Scanners use AI and sensors to find tread wear, problems, and signs of aging.

Digital records make results more steady and help people understand tire health.

Manual gauges do not have pictures and depend on skill, which can cause mistakes.

Tire tread detectors with scanners are better than manual gauges in precision, consistency, and reliability. They make tire checks faster, more correct, and more trustworthy for everyone.

Tire Tread Scanner Technology

How Scanners Work

Detectoare de adâncime a benzii de rulare use special sensors to check tread depth. Some sensors touch the tire, while others do not. Non-contact scanners use lasers or light to scan the tire. They do not press on the rubber. Computer vision looks at images to study tread depth and wear. The scanner collects thousands of points from the tire. This gives very exact and automatic measurements. Some handheld scanners are small and have a digital screen. They can work alone or with a phone or tablet. Technicians, fleet managers, and car owners use these scanners. They need quick and trusted tire checks. The scanner finds grooves by itself and uses special math to measure tread. Patented sensors and calibration tools help keep results correct for a long time.

Component | Descriere |

|---|---|

Sensor Type | Laser or structured-light, non-contact |

Metoda de măsurare | Automated, scans entire tire surface |

Groove Recognition | Automatic, uses computer vision and algorithms |

Usage Modes | Standalone or paired with mobile app |

Reporting | Real-time display, inspection report generation |

Conectivitate | Bluetooth/Wi-Fi, ready for integration |

Target Users | Technicians, fleet managers, vehicle owners |

3D Modeling and Data Output

Tire tread detectors use 3D modeling to show tire wear. Laser scanning makes a 3D map of the tread. This map turns into a 2D chart to find features. The scanner splits up tread and groove data for better modeling. Algorithms group patterns and fix edges, so people do less work. Deep learning sorts out problems and helps study tread shapes. Using both camera and laser data makes finding wear easier. This method helps redesign tires and spot wear more accurately. The scanner gives digital reports. Users can see these on phones or computers.

Tip: 3D modeling lets tire tread detectors find small problems and uneven wear that manual gauges often miss.

Detection Accuracy

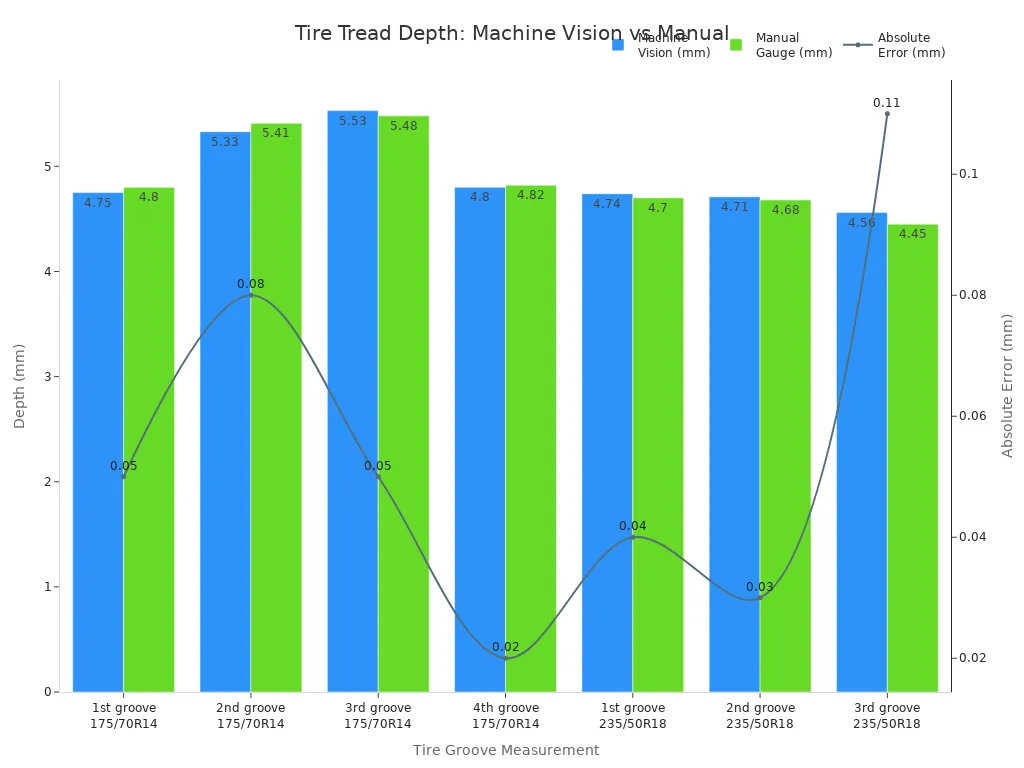

Tire tread detectors are very accurate because of advanced sensors and calibration. Scientists made printed sensors with carbon nanotubes. These sensors watch tread wear in real time with 99% accuracy. They can spot tiny changes in tread depth and give steady results. A study compared machine vision detectors to manual gauges. The errors were less than 0.2 mm and between 0.41% and 2.47%. The scanner finds grooves and measures depth as well as manual gauges. Special math and calibration tools make results even more reliable.

Caracteristică | Scaner pentru adâncimea benzii de rulare | Manual Gauge |

|---|---|---|

Tehnologie | Laser scanning technology, 3D modeling | Mechanical, single-point |

Precizie | ±0.2 mm, high-precision detection | ±0.01 mm, user-dependent |

Eficiență | Automated measurement, fast | Manual, slower |

Timp de inspecție | Secunde pe anvelopă | Minute pe anvelopă |

Reporting | Digital, real-time, app integration | Manual, paper records |

Conectivitate | Bluetooth/Wi-Fi, integration ready | Niciunul |

Tire tread detectors with laser scanning and 3D modeling are more accurate, faster, and better at reporting than manual gauges. These tools help people spot tire wear, keep cars safe, and make smart choices using data.

Manual Gauges

How Manual Gauges Work

Manual gauges are simple tools for checking tire tread depth. The most common way uses a small probe or pin. This pin slides into the groove of the tire tread. The user puts the gauge on the tire and pushes the probe down. The probe stops when it touches the bottom of the groove. The gauge shows the depth on a scale in millimeters. Technicians and car owners like this tool because it is easy to carry. It does not need batteries to work. Manual gauges are good for quick checks, but they only check one spot at a time. People use them to see if the tread is deep enough for safe driving.

Tip: Clean the tire before using a manual gauge. Dirt or stones can change the measurement.

Single-Point Measurement

Manual gauges check tread depth at just one spot. The user picks a place on the tire and measures there. This method does not scan the whole tire. If the tire wears unevenly, the gauge might miss thin spots. Technicians often check more than one place on each tire. This helps them get a better idea of the tread. But this takes longer and may still miss some problems. Checking only one spot can miss signs of wear or damage. Fleet managers and auto shops use manual gauges for fast checks. They know this method has limits.

Caracteristică | Manual Gauge |

|---|---|

Measurement Type | Single-point |

Viteză | Lent |

Data Recording | Manual, paper |

Precizie | User-dependent |

User Error

Manual gauges need the user to be careful and skilled. If the gauge is not flat on the tire, the reading can be wrong. Pressing too hard can squish the rubber and give a bad result. Picking the wrong spot can miss worn areas. Sometimes people forget to check all the grooves. This means the results are not complete. User mistakes make manual gauges less reliable than digital scanners. Technicians must be careful and do the same steps every time. Training helps people make fewer mistakes, but human error is still a risk.

Note: Manual gauges cost less than digital scanners. But users must be careful to avoid mistakes.

Accuracy in Tire Tread Measurement

Factors Affecting Accuracy

Many things can change how accurate tire tread measurement is. The way you measure tread depth matters a lot. Spot checks, like the penny test, only look at one place. They often miss uneven wear on the tire. Zone methods check several places and give a better average. AI-powered scanners measure thousands of spots at once. This helps lower human mistakes and makes results better. Putting the gauge in the right spot is important. The user must hold the tool straight and press evenly. Digital or calibrated tools help make results more trustworthy. Checking many spots around the tire helps find wear patterns and shows the full tread health.

Zone and AI methods check more places and are more accurate.

Using the tool the same way each time is important.

Digital tools help stop user mistakes.

Environmental Impact

Weather and dirt can change tire tread measurement. Wet or dirty tires may give wrong results. Dirt or rocks stuck in the tread can change the reading. Hot or cold weather can make rubber softer or harder. This can change how the tool pushes into the tread. Bright sunlight or bad lighting can make manual gauges hard to read. Technicians should clean the tire before checking and use good lighting. Some scanners have special modes for rain to keep results correct. These features help users measure tread and find wear patterns better.

Tip: Always clean the tire and look for dirt before measuring tread depth to get the best results.

Calibration

Calibration makes sure tire tread tools give correct results. Manual gauges need to be checked often to stay accurate. If the scale gets worn or bent, the reading can be wrong. Digital and laser scanners have systems that check themselves. These systems warn users if something is not right. Good calibration helps users trust their tread depth measurements. Checking calibration often helps find wear patterns and keeps data good. Fleet managers and technicians should follow the maker’s rules for calibration. This helps keep tread depth checks right and helps find tire wear early.

Tipul de instrument | Calibration Needed | Calibration Method |

|---|---|---|

Yes | Manual check, visual | |

Yes | Automatic, self-check | |

Laser Scanner | Yes | Built-in, software alert |

Real-World Use

Professional Settings

Tire inspection is very important in car shops. It helps keep cars safe and service good. Many shops still use manual gauges. But these tools can give different results for each worker. This can make service uneven and hurt customer trust. Manual checks also take longer, which slows work when shops are busy. Shops using digital tire tread detectors see big changes. These scanners use AI to check the whole tire and make clear reports. Shops can show these reports to customers. This builds trust and helps sell more services. Many repair shops now think tire tread detectors are needed to keep up with others.

Manual tire checks can be different for each worker, so results are not always the same.

Digital tire tread detectors help stop mistakes and make customers feel better.

Scanners make reports that help shops explain tire wear and safety.

Personal Use

Tire tread detectors are good for people who own cars too. Mobile scanners let people check tire tread with a phone or tablet. This makes checking tires easy and fast at home or anywhere. People save money because they do not need special tools. Real-time data helps people know when to change tires or fix them. Over time, these tools help people watch tire wear and keep cars safe. The simple design means anyone can use a scanner, not just car experts.

Mobile tire tread detectors help people check tires on time.

Real-time data and reports help people make safe choices and trust their repair shops.

Eficiență

Efficiency is important for shops and fleets. Most fleets still use manual gauges. These only check one spot and need people to write down results. This makes tire checks slow and can cause mistakes. Digital tire tread detectors scan the whole tire fast and save results by themselves. Fleets using scanners finish checks faster, make fewer mistakes, and get better data for planning. Good tire checks help fleets save money by stopping breakdowns and using less fuel. Some scanners cost more at first, but they save money and time later.

Digital tire tread detectors check more of the tire and finish faster.

Automatic data recording helps plan repairs and stops delays.

Better efficiency means safer cars and lower costs for fleets.

Data and Record-Keeping

Digital vs. Manual Records

Keeping good records is important for tire safety. Manual records use paper or handwritten notes. This takes more time and can cause mistakes. People might lose papers or write wrong numbers. When shops get busy, manual records slow things down. Sometimes, over 40% of manual tire records have mistakes or missing parts.

Digital record-keeping makes things easier. Technicians use phones or tablets to scan and save tire data fast. OCR and AI help get details quickly and correctly. Digital systems cut human mistakes by up to 80%. They let people see tire info right away using the cloud or local storage. Mobile scanning works even without the internet, so it can be used anywhere. Digital records help manage inventory and track tire history better.

Tip: Digital tire records help shops and fleets act fast on recalls and keep better track of tire health.

Metodă | Viteză | Error Rate | Accessibility | Data Loss Risk |

|---|---|---|---|---|

Manual | Lent | Ridicat | Scăzut | Ridicat |

Digital | Rapid | Scăzut | Ridicat | Scăzut |

Integrare

Modern tire tread scanners work well with business and fleet systems. These scanners connect to fleet software using APIs, mobile SDKs, or cloud tools. When a technician scans a tire, the data links to the car’s ID, like the VIN or license plate. This info goes into the fleet’s digital records.

Integration lets managers see tire health, car status, and service needs in one place. The system can send alerts for new tires or service based on tread depth, pressure, and miles. Automatic reports help with rules and make checks easier to follow. AI and Bluetooth sensors give even more details and better accuracy.

A recent survey showed only 18% of fleets use digital tire data in their IT systems. Most still use manual entry, which causes more mistakes. As more companies use digital integration, they get faster service, better safety, and lower costs.

Note: Integrated tire data helps fleets plan repairs, cut downtime, and keep every car safer.

Choosing the Right Method

Key Considerations

Picking the best way to measure tire tread depends on a few things. People should think about how accurate the tool is and if it keeps track of data. They should also look at how easy it is to use, how much it costs, and if it fits their needs. The table below shows how tire tread scanners and manual gauges are different in these ways:

Consideration | Tire Tread Scanners (Digital Gauges) | Manual Gauges |

|---|---|---|

Accuracy and Precision | High precision due to digital sensors; eliminates human error; detects minute tread depth changes. | Physical measurement; subject to human reading error; provides direct but less precise data. |

Data Logging & Monitoring | Stores and tracks tread depth over time; helps predict tire lifespan and identify wear patterns. | No data logging; used for immediate, one-time measurements. |

Integration with Digital Platforms | Often integrates with smartphone apps or software for analysis and record-keeping. | No integration; purely mechanical device. |

Ease of Use and Readability | Clear digital display; user-friendly interface; accessible to users with varying technical skills. | Simple to use; requires no batteries or software; quick physical checks. |

Affordability | Generally more expensive due to technology and features. | More affordable and accessible for most users. |

Practical Use Cases | Suitable for detailed monitoring, fleet management, and professional use. | Ideal for quick checks, individual drivers, and basic monitoring. |

Limitations | Requires batteries/software; may be more complex for some users. | Limited precision; no data tracking; relies on user skill for accuracy. |

People should also remember the rules about tire tread. Laws say tires must have a certain tread depth, like 2/32″ for cars. These rules usually talk about using manual tools, like tread depth gauges or simple tests. There are no official rules for scanners yet, so people use manual checks to follow the law. Checking tires often with manual gauges helps drivers stay safe and follow the rules.

Tip: Fleets and shops can work faster and keep better records with digital tire tread scanners. For people who just want a quick check, manual gauges are cheap and easy to use.

Tire tread scanners are more accurate and faster than manual gauges. They use special optical and laser tools to scan tires quickly. These scanners find uneven wear and help stop roadside problems. Many fleets and makers use these sensors for safer cars and lower costs. Checking tire tread often is very important for safety. Studies show worn tires make crashes more likely. The table below shows how tread depth changes accident risk:

Tire Tread Depth (in 32nds) | Accident Rate (%) | Safety Recommendation |

|---|---|---|

Near full | 2.4 | Check tires often |

4/32″ | ~8 | Shop for new tires |

0-2/32″ | 26 | Replace tires immediately |

Technicians, fleet managers, and car owners should check tire tread often to keep cars safe.

Întrebări frecvente

What makes a tire tread scanner more accurate than a manual gauge?

A tire tread scanner uses lasers and special light math. It scans the whole tire, not just one place. This helps find small changes in tread depth. The scanner gives results that are more reliable than a manual gauge.

Who can use a handheld tire tread scanner?

Technicians, car owners, and tire shops can use these scanners. Fleets and inspection stations also use them. The device works alone or with a phone or tablet. This makes it easy to use and share reports.

How does a tire tread scanner display results?

The scanner shows numbers and color bars on its screen. You can see battery, Bluetooth, and Wi-Fi icons too. If you use a phone or tablet, it makes detailed reports about the tire check.

What are the main benefits of using a tire tread scanner?

Very accurate measurements (up to 0.1 mm)

Fast checks (all tires in about 90 seconds)

Saves data and makes reports automatically

Bluetooth and Wi-Fi make sharing easy

Can a tire tread scanner detect problems other than low tread depth?

Yes. The scanner checks for very worn tires and uneven wear. It finds signs of too much or too little air. It gives alerts and advice for fixing problems after the check.

Vezi și

Step By Step Guide To Measuring Tire Tread Depth

Înțelegerea detectoarelor inteligente de bandă de rulare și funcția lor

Importanța verificărilor regulate ale adâncimii benzii de rulare pentru siguranță